Then we descended back down into the gloom. All told we rode just short of 30 miles with over 2000 feet of climbing.

Friday, June 27, 2025

The Shore

Then we descended back down into the gloom. All told we rode just short of 30 miles with over 2000 feet of climbing.

Tuesday, June 10, 2025

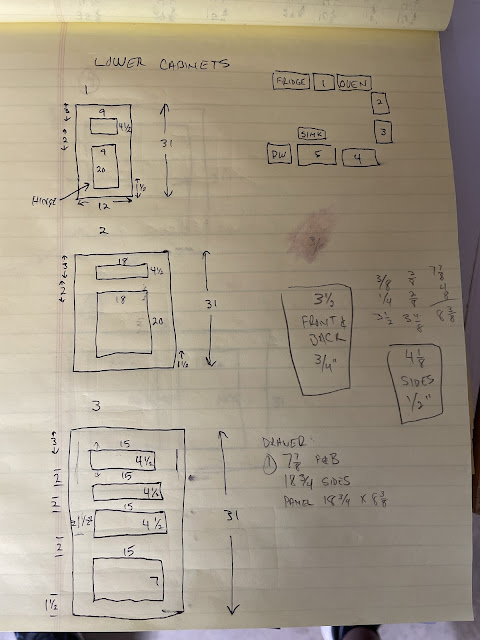

The Doors

One of the renovation tasks we decided to tackle ourselves was the kitchen cabinets. Replacing cabinets is a very expensive proposition, and it requires a permit. We decided to "reface" the old cabinets instead. Here's the before picture from our old rental company.

Pretty hideous, right?

The first order of business was to remove the doors and drawers, patch the holes, and let our professional painters do their thing.

Going from dingy white to gray was an immediate improvement.

Then it was time to make a door prototype. I watched a few videos about making "budget shaker doors" and decided to use 1/2" maple plywood with a 1/4" maple border. While it came out OK, it didn't have the quality I was looking for.

I also needed to replace the drawers. The old ones were a little small for the cabinets, so I built the scrap wood prototype a little wider so there wouldn't be as much slop and play.

On the next trip to Tahoe we checked the fit and everything was perfect.

Time to go into production.

I watched a few more videos and decided to make true shaker cabinets. We would go the MDF route because it's inexpensive, easy to work with, and the doors would be painted anyway.

I took all my measurements and performed the calculations to build everything.

I purchased the components to build a fairly professional table router setup. It was expensive, but very much worth it.

This allows you to route all the rails and styles with precision.

Unfortunately my trusty old Craftsman table saw bit the dust during this project.

It was replaced with this DeWalt portable unit that turned out to be so vastly superior that I should have bought one years ago.

Assembly went pretty quickly and soon we had a bunch of doors and drawer fronts.

Each one had to be painstakingly sanded to smooth out the seams and round all the sharp corners.

Then it was off to paint, a task that Jennifer handled. She learned quickly and did a great job.

She pre-sprayed all the drawer parts so when I tacked them together, they were mostly painted.

Everything went up pretty easily and lined up well.

I made one calculation mistake thinking I would use 1.5 inch overlay hinges everywhere. It turned out that a few doors needed 3/4" hinges. No big deal, I was able to cut down the offending doors and replace one rail without too much effort.

Installing the drawer fronts was easily the most difficult part. Getting them level and lined up with both each other and the cabinet doors proved tricky.

All that was left was installing the black hardware. It was a piece of cake with the jig I bought.

In the end we were pretty happy with the finished product.

Were they perfect? No. But we learned a lot and next time we will edge much closer to the perfection we always seek with home improvement projects.

Later.

Wednesday, June 04, 2025

The Wall

After recently finishing the remodel of the Tahoe condo, I thought I would highlight some of the cooler improvements we made.

The bar area was pretty terrible: Tile countertop, hideous gray and pink tile on the wall, and a high bar level which closed off the room a bit.

We tore out all the tile and I cut down the wall.

I installed sheetrock so I had something to glue the wall treatment to.

In the end it turned out great. I will definitely use this stuff again for a feature wall.

Later.

.jpg)